What is barcode and how to Inspection ?

Having correct, readable barcodes on packaging is crucial to guarantee the efficiency of inventory management, tracking & tracing and product handling throughout the supply chain. Therefore, ensuring that all approved packages have correct, readable barcodes, which includes verification of the barcode’s grading and quality, is an essential part of the general checking criteria of on-site product inspections.

There are many obvious barcode errors encountered during barcode verifications, especially with its printing quality. But here are the two common issues that can be quite challenging to detect as a defect:

1. Code 128 is a high-density linear barcode symbology defined in ISO/IEC 15417:2007. It is used for alphanumeric or numeric-only barcodes. Different from other formats such as UPC and EAN which can only use numbers as characters, in Code 128 barcodes, any symbol can be used as a character, including spaces. However, it sometimes occurs that the number printed below the barcode has a space within the numbers, but the number generated by the barcode scanner has none. As it’s “just a space”, it can easily pass undetected.

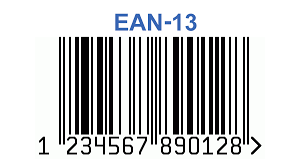

1. The EAN-13 is a 13-digit barcode and it’s used more than any other barcode worldwide. The EAN-13 barcode encodes a GTIN-13 and is used to identify individual items at retail point of sale. For this type of barcode, it sometimes occurs that the number ”0” printed in front of the other numbers below the barcode does not show in the number generated by the barcode scanner. As it’s just a “0” in front of a number, it can also go undetected.

Barcoding errors are completely preventable once you know what to look out for. V-Trust Engineers have extensive knowledge and inspection experience and can ensure that your products meet your requirements as well as the appropriate regulations for the country and region they will be marketed in, paving the way for risk-free transactions, safety and compliance.