According to the special requirements of the customer, 3% is sampled, so the number of single samples is 75, and the AQL is 2.5 4.0. Informing the customer that 3% of the camping air mattress inspection will reduce the number of samples, and the risk that the corresponding quality problems cannot be found by random sampling will also increase accordingly. .

Inspection points for camping air mattresses:

1. Special checkpoints

2. Appearance and craftsmanship

3. Quantity compliance

4. Product and Packaging Compliance

5. Data measurement and field test

Camping air mattress inspection

1. Special checkpoints

This customer specifically requested that the inspection label of the camping air mattress be checked. Check the six-sided labels of the outer carton, and use the scanner to check the bar code of the outer carton and the bar code of the product sales packaging.

Label Check

2. Appearance and craftsmanship

According to AQL (acceptable quality limit) 2.5, 4.0 inspection, the sampling number is 75, the camping air mattress inspection actually found 2 minor defects, namely untrimmed thread ends and edge creases.

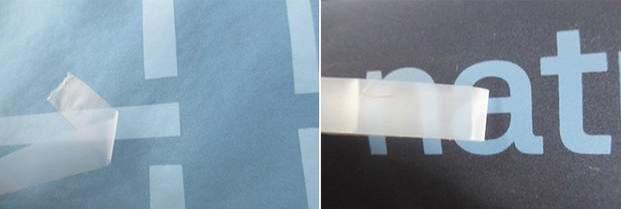

Minor defects - untrimmed thread ends (left), edge creases (right)

3. Quantity compliance

The number of products in the inspection order for the camping air mattress is 2,500, and the number of shipments is 2,500. The actual completed quantity: 1,032 packed and 1,468 unpacked; number of boxes: 363 packed and 637 unpacked.

4. Product and Packaging Compliance

Check the relevant data according to the inspection data of the camping air mattress provided by the customer: technical documents, labels, box marks, and product specifications.

Product packaging inspection

5. Data measurement and field test

01. Box drop test

Referring to the ISTA 1A standard, after being dropped 10 times, the packaging or camping air mattress inspection products must not have fatal defects or serious defects.

02. Product size/weight measurement

According to specification or reference edition requirements. Use +/- 3% as tolerance if possible unless otherwise specified.

Product size check

03. Barcode Scanning Check

The inspection barcode of the camping air mattress can be scanned, and the scanning result is correct.

04. Special function check (for which must be fully installed to check)

The camping air mattress inspection must have all nominal functions such as installation/adjustment, switch, setting, display, actual use, etc.

Functional check

05. Coating Test

Test all camping air mattresses by painting, stamping, coating, printing with 3M 600 (or similar tape). After the test, no more than 10% of the area should fall off.

06. Wipe test

Rub the sample to be tested 10 times with normal pressure with the designated white cloth (a distance of 10 cm in about 10 seconds). Dry or wet collisions follow the above method. Evaluate for color transfer.

Screen printing fastness check

07. Weight Test

120kg/240kg/2 hours.

Static pressure test

08. Color Check

Pantone color card for color checking. Pantone: 18-4036TPG, 19-4011TPG, 19-0506TPG, 18-4036TPG, 284U

Pantone color card for color checking

09. Air leak check

No air leaks

After the inspection of the above inspection items, it is concluded that the inspection and test conclusions of the camping air mattress are in line with

Overall conclusion of inspection of camping air mattresses: not compliant

The inspection quantity of the camping air mattress is inconsistent, and the final inspection is the most effective inspection method to confirm the quality level of the whole batch of goods. It usually requires 100% of the goods to be produced and at least 80% of the goods to be packed into cartons. This single product-camping air mattress inspection actually found that 100% of the 2,500 products were completed, but only 47.8% of the products were put into the box. Therefore, the camping air mattress inspection concluded that it did not meet the requirements, Result is Fail.

QCANT™ Quality Control Service Provider,Partner of SGS,TUV,Intertek provide variety of professional inspection and auditing services with 180+ inspecters to ensure goods meet buyer requirements and regulations in the supply chains. QCANT Pricing begin with ALL included only $198/MD for Inspection in China, 5 minutes to make an online booking , get order scheduled and 99% receive report within 24 hours