Qcant™ Product Defects | How can you identify them?

Sometimes what you consider a "defect" is not a product quality problem in eyes of your manufacturer. To avoid misunderstandings and large loss due to incorrect quality in the future, better to establish the QC vocabulary with your supplier at the first steps of your negotiations.

For that, many importers choose to create a list of acceptable and unacceptable product defects and pass it along with the purchase order to supplier. In this article we will share with you some tips and examples on how to identify product defects.

Product quality is assessed and accepted worldwide based on the AQL standard (click here to learn how to read AQL). AQL indicates the maximum acceptable defects for a certain sample size of products inspected.

Usually in Production and Quality Control defects are classified in three types: Critical, Major and Minor.

Critical defects

Critical defects are defined as non-compliance with mandatory regulations that may harm the consumer's health, safety, or the environment. These include defects of product functionality and safety, as well as defects in product quality, i.e. appearance.

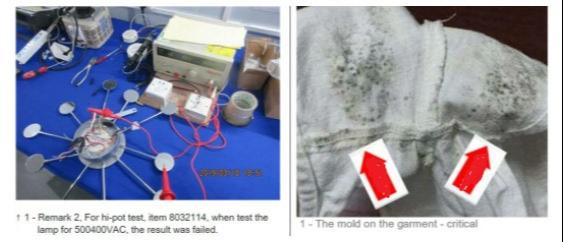

For electrical products, an example of a critical defect would be if your product doesn’t pass a hi-pot test or earth continuity testing, indicating unsafety of the product that poses a risk of electric shock.

For textile products, the detection of broken needles in a textile piece will be considered a critical defect, and for children's toys - the presence of sharp corners of plastic/metal that can harm a child is considered critical.

Also, defects related to non-compliance with hygiene, product storage conditions and the risk of spreading diseases, for example, the presence of hair, mold, blood drops on the product or packaging, traces of insects, etc.

The default tolerance for critical defects according to AQL is 0, which means that even if one critical defect is detected, it is not recommended to accept the batch for shipment, and better to recheck the whole production again for defects.

Major defects

The second most important set of defects are major defects, which affect the functionality of the product. These defects are likely to result in function failures or reductions of the usability of products or obvious appearance disfiguration, which may affect the salability of products.

An example of major defects in electrical products is non-compliance with the specified product characteristics. For example, if the actual power of your power bank does not match the power indicated on the label - this case happens quite often, because suppliers replace the batteries inside the power bank (or insert a dummy) and pass them off as more powerful.

Loop stitches and open seams are examples of major defects in the textile inspections. Such defects can lead to poor structure, the product might lose its marketable appearance. Incomplete or excessive stuffing of plush toys, for example, is also considered a major defect.

The classification itself based on well-established examples from inspection practice. You can add your own examples and create a list of major defects based on your expectations about the quality of your own product. Some customers include defects of the logo and marking in this list, as misplacements can have a bad effect on the brand image.

The most widely used tolerance of major defects according to AQL is 2.5. For a sample size of 200 pieces, the acceptable number of defects in this case is 10 pieces. If an inspector finds 11 or more defects in a sample size of 200 pieces, it is recommended not to accept the batch.

Minor defects

Product defects that will not reduce the usability or function of the product, but are beyond the defined quality standard, are minor defects. These are mainly defects in product’s aesthetics and appearance that are less noticeable, and which are located on non-central parts (parts B and C) of the product.

Spots, scratches, dirt and dust marks on the product, slight deformations or slight gradation of color - all these are examples of minor defects that can have a negative impression on the consumer due to an imperfect product appearance.

It should be understood that even the smallest speck of dust can affect the quality of products. For example, dust inside the LED panel or light bulb will leave dark spots on the panel itself, and the light distribution will not be ideal.

Again, you can make a list of minor defects yourself according to your understanding of the quality level of your products and their compliance with the expectations of your customers.

The default acceptance limit of minor defects according to AQL is 4.0. For a sample size of 200 pieces, the acceptable amount of minor defects is 14 pieces. If an inspector finds 15 or more defects in a sample of 200 pieces, it is recommended not to accept the batch.

Should I accept defective products?

It is necessary to understand that product defects are present in any production in more or less quantity, so it is almost impossible to achieve complete absence of defects in the order.

It is recommended to replace or repair defective products, as well as make a list of preventive measures for the occurrence of such a defect in the future. You can also buy a defective product at a discount, for subsequent sale by promotion, etc.

Read our next article: QC tips | How to set a product’s Quality level for your supplier to know more on instruments that product developers and quality managers use when setting the quality level for their products.

To check whether quality meets your requirements, we are always glad to offer help. QCANT offers a variety of Quality Control services, such as product inspection, factory audit and laboratory testing in Asia.

Feel free to visit our website (www.qcant.com) to get to know more about our company and services, and should you have any questions, please feel free connect with us via cs@qcamt.com.